Understanding the Tevo Tarantula

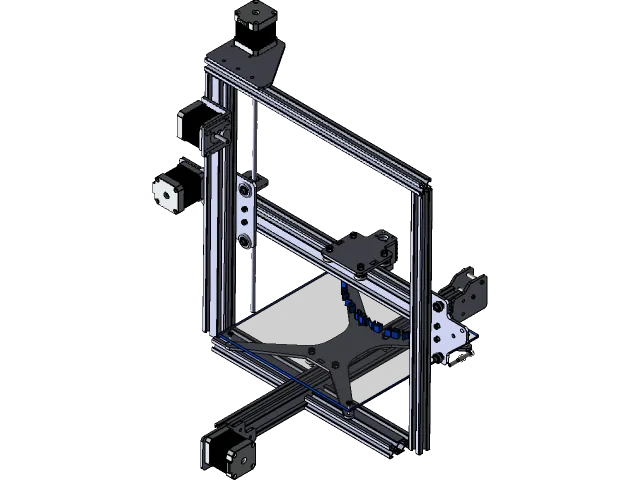

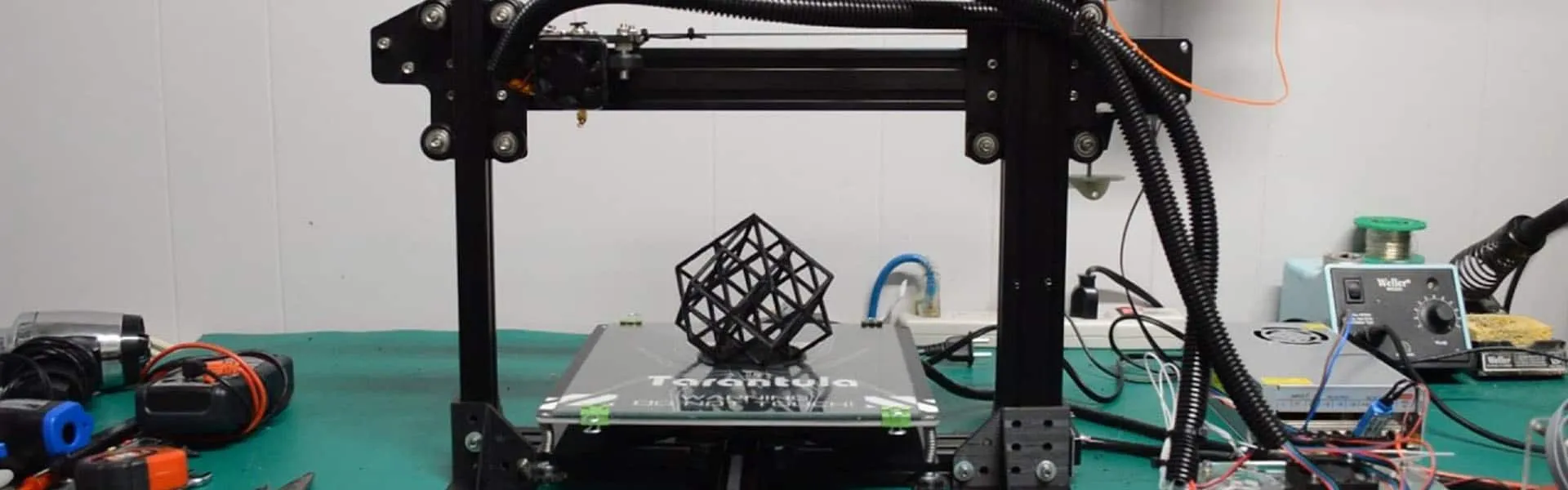

The Tevo Tarantula is a popular 3D printer known for its affordability and ease of assembly, making it a favorite among hobbyists and beginners. Launched in the past, it quickly gained traction within the 3D printing community. Its open-frame design allows for easy access and modifications, and its relatively simple construction means that users can quickly get started with printing. However, like any budget-friendly machine, the Tevo Tarantula has its limitations. Understanding these limitations and knowing how to address them through upgrades is crucial for maximizing its potential and achieving high-quality prints. This article will guide you through three key upgrades that can significantly enhance your Tevo Tarantula’s performance.

Stock Tevo Tarantula: Limitations

While the Tevo Tarantula offers a great entry point into 3D printing, several areas can be improved. The stock bed leveling system often requires manual adjustment, which can be time-consuming and frustrating. The extruder design, while functional, can be prone to filament jams and inconsistent feeding. Furthermore, the original firmware may lack advanced features and optimization options. These limitations can lead to print failures, poor print quality, and a steeper learning curve for new users. Overcoming these challenges through strategic upgrades is the key to unlocking the full capabilities of your Tevo Tarantula and achieving professional-grade results. Addressing these issues can significantly improve the overall user experience and print success rate.

Common Issues Faced by Users

Users often report several recurring issues with the stock Tevo Tarantula. Bed adhesion problems are common, leading to prints detaching from the bed mid-process. The extruder can struggle with flexible filaments and may require frequent maintenance to prevent clogs. Inconsistent layer adhesion and stringing are also frequently cited, affecting the overall quality and aesthetics of the prints. Furthermore, the lack of advanced features in the stock firmware can limit the printer’s capabilities and the user’s ability to fine-tune settings for optimal results. Addressing these common problems through targeted upgrades can significantly improve print quality and user satisfaction, transforming the Tevo Tarantula into a more reliable and efficient 3D printing machine.

Upgrade 1: Improving the Bed

One of the most critical upgrades for the Tevo Tarantula is improving its bed leveling system. A properly leveled bed ensures that the first layer adheres correctly, which is essential for successful prints. Upgrading the bed can significantly reduce print failures and improve overall print quality. Several options are available, ranging from simple manual adjustments to more advanced automated systems. This upgrade is often the first step in optimizing the printer for better performance.

Why Bed Leveling is Crucial

Bed leveling is the foundation of successful 3D printing. If the bed is not level, the distance between the nozzle and the bed will vary across the printing surface. This can lead to several problems, including poor first-layer adhesion, warping, and nozzle crashes. An uneven bed causes the filament to be squished too much in some areas and not enough in others, leading to inconsistent layer adhesion and ultimately, print failure. Proper bed leveling guarantees a consistent distance between the nozzle and the bed, which is essential for producing high-quality prints.

Upgrade Options for Bed Leveling

There are various options to improve the bed leveling process on your Tevo Tarantula. These upgrades can range from simple adjustments to more complex automated systems. The choice of upgrade will depend on your budget, technical skills, and desired level of convenience. The goal is to ensure a consistently level bed surface, thereby eliminating many common print problems. The following are two common upgrades that can significantly improve the performance of your Tevo Tarantula.

Manual Bed Leveling

Manual bed leveling involves adjusting the bed height using the leveling screws located at each corner of the bed. This method requires patience and precision, as you must adjust the screws until the nozzle is the correct distance from the bed across the entire surface. This can be achieved by using a piece of paper to gauge the distance between the nozzle and the bed. Although more time-consuming, manual bed leveling is a cost-effective solution that can provide accurate results with practice. However, it requires regular checks and adjustments, especially after printing multiple models.

Auto Bed Leveling (ABL) Systems

Auto Bed Leveling (ABL) systems automate the bed leveling process, making it significantly easier and more accurate. These systems typically use a sensor to measure the distance between the nozzle and the bed at multiple points. The printer’s firmware then uses this data to compensate for any bed imperfections during printing. This technology eliminates the need for manual adjustments and ensures a perfectly level first layer every time. There are different types of ABL systems, including inductive, capacitive, and BLTouch sensors. Installing an ABL system drastically reduces the likelihood of failed prints due to bed leveling issues. Consider installing an auto-bed-leveling system for better printing results.

Upgrade 2: Enhancing the Extruder

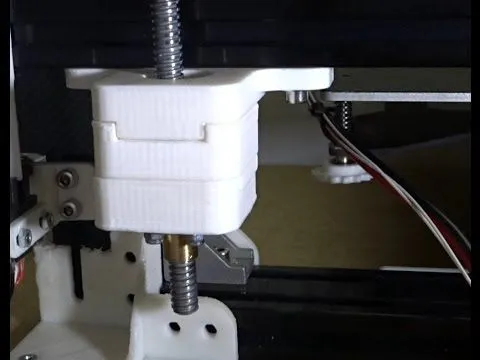

The stock extruder on the Tevo Tarantula, while functional, can be a source of frustration for some users. Upgrading the extruder can improve filament feeding, reduce jams, and allow for printing with a wider range of materials. Several options are available, each with its advantages and disadvantages. This upgrade can significantly enhance the reliability and versatility of your 3D printer.

Stock Extruder Design and its Drawbacks

The stock extruder on the Tevo Tarantula is usually a Bowden-style extruder, which means the extruder motor is mounted on the frame, and the filament is fed through a PTFE tube to the hot end. This design can have several drawbacks, including a longer filament path, which can lead to more retraction issues and filament jams, especially with flexible materials. Furthermore, the stock extruder may not provide enough force to consistently feed the filament, particularly at higher printing speeds. These limitations can affect print quality and reliability.

Upgrading to a Direct Drive Extruder

A direct drive extruder mounts the extruder motor directly on the hot end, eliminating the PTFE tube and significantly reducing the distance the filament needs to travel. This design offers several advantages, including more precise filament control, reduced retraction issues, and the ability to print with a wider range of materials, including flexible filaments. While a direct drive setup may add weight to the print head, the benefits in terms of print quality and reliability often outweigh the drawbacks.

Benefits of Direct Drive

Direct drive extruders offer several key advantages. They provide better control over filament flow, which leads to improved print quality and fewer issues like stringing and oozing. The shorter filament path allows for faster retractions and more precise movements, improving the accuracy of fine details. Direct drive extruders are particularly well-suited for printing with flexible filaments, as they provide better grip and prevent filament buckling. This upgrade will surely improve your prints.

Considerations for Direct Drive

When upgrading to a direct drive extruder, there are a few factors to consider. The added weight on the print head may require adjustments to the printer’s settings, such as acceleration and jerk values. You may also need to adjust the Z-offset to compensate for the change in the position of the nozzle. Ensure that the direct drive setup is compatible with your hot end and that you have sufficient cooling for the extruder motor. This upgrade requires planning to ensure a good fit.

Upgrade 3: Boosting the Firmware

Upgrading the firmware is a crucial step in optimizing the Tevo Tarantula. The firmware controls all aspects of the 3D printer’s operation, including motion control, temperature regulation, and communication with the user. Upgrading to a more advanced firmware can unlock a range of new features, improve print quality, and enhance the overall user experience. This step will surely make your printer’s life a lot better.

The Role of Firmware in 3D Printing

Firmware is the software that runs on your 3D printer’s control board. It dictates how the printer interprets G-code instructions, controls the motors, and regulates the temperature of the hot end and bed. The firmware is essential for every aspect of printing. The stock firmware on the Tevo Tarantula may be limited in its features and optimization. Upgrading the firmware can provide access to advanced features, improved print quality, and enhanced customization options.

Benefits of Upgrading Firmware

Upgrading the firmware offers numerous benefits, including improved print quality through advanced features such as linear advance and pressure advance, which helps to reduce stringing and improve cornering. Newer firmware supports features like thermal runaway protection, which enhances safety. Firmware upgrades also allow you to customize the printer’s behavior, fine-tune settings, and add new functionalities. These additions allow you to do more with your 3D printer.

Popular Firmware Choices

Several popular firmware options are available for the Tevo Tarantula. Marlin is a widely used and highly customizable firmware that offers a wide range of features and settings. RepRapFirmware is another option known for its advanced features and ease of use. Choosing the right firmware depends on your needs and experience level. Researching the different options and comparing their features and community support can help you make an informed decision. Make sure the firmware will be compatible with your hardware.

Flashing New Firmware to Your Tevo Tarantula

Flashing new firmware involves uploading the firmware to your printer’s control board. The process typically involves connecting your printer to a computer, using a software program to upload the firmware file. The specific steps for flashing the firmware will vary depending on the firmware you choose and the control board in your Tevo Tarantula. Consult the firmware documentation and online tutorials for detailed instructions. Backing up your existing firmware before flashing is always recommended in case of any issues. Do not attempt this if you do not have experience.

Conclusion The Future of Tevo Tarantula

The Tevo Tarantula is a capable 3D printer, and by implementing these three key upgrades, you can significantly enhance its performance. Improving the bed leveling system, upgrading the extruder, and boosting the firmware can all lead to better print quality, increased reliability, and a more enjoyable 3D printing experience. As you continue to use your Tevo Tarantula, experimenting with these upgrades and fine-tuning your settings will allow you to achieve even better results. With these upgrades, you can unlock the full potential of your Tevo Tarantula and continue to enjoy the world of 3D printing. Enjoy the new printer, and continue to seek knowledge about printing.